本產(chǎn)品是近幾年來我廠有關(guān)人員在不斷實踐的基礎(chǔ)上,自行研制、開發(fā)的一種節(jié)能、高效、環(huán)保型快速式浮選機。

This machine is a kind of energy-saving, high-efficiency, and pollution-free flotation machine developed by relevant persons in our factory in recent years during their constant practice.

本產(chǎn)品具有占地面積小,能耗低,操作簡單,維修量小,處理量大,精煤回收率高等特點。并且一般情況下浮選精煤灰分可根據(jù)合同需要在6%-12%之間隨意調(diào)整,尾煤灰分可達45%-70 %之間,可從噸煤泥中提取60%-90%之間的合格精煤。

This product has characteristics such as small occupying land, low energy consumption, easy operation, infrequent maintenance, large handling capacity, and high recovery rate of concentrate. Besides, the ash content of flotation concentrate can normally be adjusted freely within 6% to 12% according to contract needs. The ash content of tailings can be adjusted within 45% to 70%. A total of 60% to 90% of qualified concentrate can be extracted from the coal slime.

正常情況下,浮選精煤數(shù)量約占洗精煤產(chǎn)量的10%左右。

In most cases, the amount of flotation concentrate accounts for around 10% of that of the fine washing coal.

一、用途

I. Application

該設(shè)備主要用于從洗煤水中提取精煤,適用于和15平方以下的所有跳汰洗煤機、側(cè)鼓式洗煤機、篩下空氣室洗煤機配套使用。

This equipment is mainly used to extract clean coal from the coal washing water, and can be used with all jig coal washers, side-drum coal washers, and air chamber underbed coal washers occupying less than 15m2.

二、結(jié)構(gòu)特征

II. Structural Feature

該設(shè)備占地小,每臺占地僅需6-7×6-7(㎡);易操作,每臺每個班僅需一人;維修量小,僅有兩臺泵的保養(yǎng)與維修;電耗低,配套功率在50-100千瓦之間。

Such equipment occupies a small land, only 6-7×6-7(㎡) for each, and is easy to operate. Only one person is enough to operate each of such machines in one shift. Only two pumps need to be maintained. It does not consume much power and its rated power is 50 – 100KW.

洗水無須濃縮,即可將浮選設(shè)備串入洗煤系統(tǒng)中進行正常生產(chǎn)(可節(jié)約濃縮設(shè)備投資25萬元左右)。

The washing water does not need to concentrate and the flotation equipment can be put in the coal washing system for normal production (Around RMB 250,000 spent purchasing concentrator can be saved).

三、工作原理

III. Working Principle

打開上料泵后,洗煤水先經(jīng)過預(yù)處理器,使經(jīng)注藥器滴入的起泡劑和捕收劑與洗煤水充分混合。

After the feed pump is started, the coal washing water first flow through the preprocessor, to get the foaming agent and suction supporting agent dripped from the reagent injection instrument to be intensively mixed with the coal washing machine.

進入浮選柱體內(nèi)的洗煤水,由上而下與由下向上運動的泡沫,發(fā)生連續(xù)不斷的充分碰撞,從而完成了從粗選到精選再到掃選的三個過程。

The coal washing water getting into the flotation column from top to bottom collides continuously with the bubbles moving from bottom to top, so as to finish three processes from roughing, to cleaning, and then to scavenging.

經(jīng)過以上三個過程未能充分上浮的精煤,從柱體底部進入循環(huán)系統(tǒng),通過強制循環(huán),使一少部分經(jīng)掃選后仍未浮上的精煤,經(jīng)運動、充氣、再混合后,伴隨氣泡充分上浮,使系統(tǒng)效果更趨完善。

The clean coal which is not able to fully float after these three processes enters the circulating system from the bottom of the column. Through forced circulation, a small part of the clean coal which does not float fully floats upward along with the bubbles after movement, aeration, and mixing again, to enable the system to be more effective.

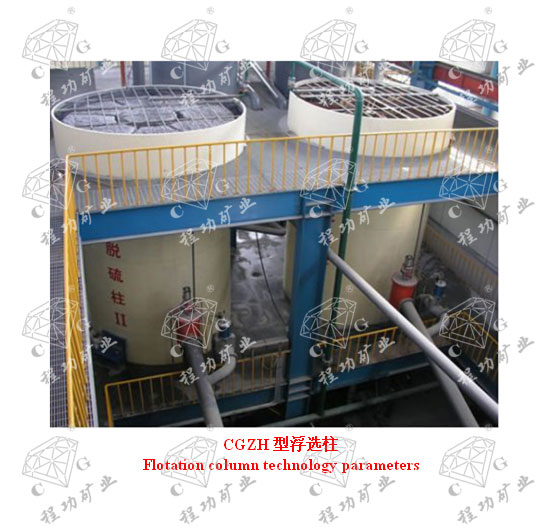

四、技術(shù)參數(shù)

Ⅳ. Technical Parameters

| 型號 | 吞吐量 | 入料濃度 | 浮選動力 | 壓濾動力 |

|---|---|---|---|---|

| mm | t/h | g/升 | kw | kw |

| CGZH2500 | ≤120 | ≤120 | 15+30 | 37+10 |

| CGZH2900 | ≤150 | ≤120 | 22+37 | 37+15 |

| CGZH3250 | ≤250 | ≤120 | 30+55 | 37+20 |